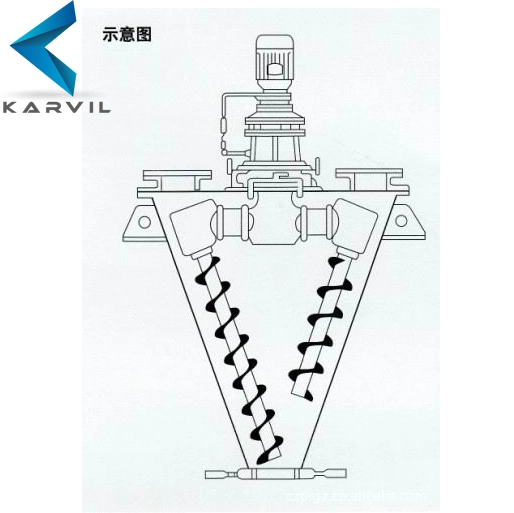

WH series double helix cone mixeris a mixing equipment with new style, high efficiency and high precision, which is widely used in pharmaceutical, chemical, feed and other industries.

The material is made to conduct a compound motion in the cone because of the rotation and revolution of the screws.

Main Features

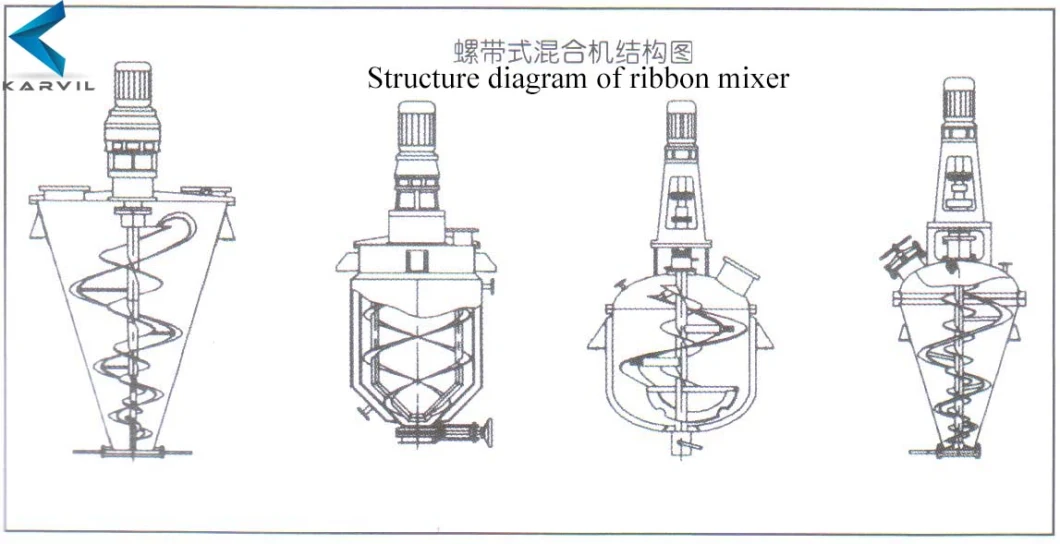

1.This model of machine can be equipped with single screw, double screws, tri-screws.

2. It can be equipped with flying cutter, spraying device so as to meet the requirements of special technical requirements.

3. The discharging valve adopts two ways, manually or pneumatically.

4. The motor power can be increased for special material.

5. Compared with the drum mixer, the energy-saving effect is remarkable, only about one tenth.

6. The mixing process is gentle, the material will not produce pressure feed, wearing, and overheating.

7. The mixed preparation is stable without stratification and segregation.

8. The mixer is sealed and dust-free, easy to operate and easy to maintain.

9. PLC controlled.

Technical Parameters

| Spec. | Total volume (m³) | Load factor | Equipped Power (KW) | Overall dimension (mm) | Weight (Kg) |

| WH-0.1 | 0.1 | ≤0.6 | 1.5 | 1569 Φ702 | 250 |

| WH-0.3 | 0.3 | ≤0.6 | 2.2 | 1929 Φ920 | 550 |

| WH-0.5 | 0.5 | ≤0.6 | 3 | 2322 Φ1124 | 660 |

| WH-1.0 | 1.0 | ≤0.6 | 4 | 2869 Φ1480 | 1200 |

| WH-1.5 | 1.5 | ≤0.6 | 5.5 | 3140 Φ1633 | 1350 |

| WH-2.0 | 2.0 | ≤0.6 | 5.5 | 3489 Φ1816 | 1500 |

| WH-3.0 | 3.0 | ≤0.6 | 7.5 | 3747 Φ2210 | 2300 |

| WH-4.0 | 4.0 | ≤0.6 | 11 | 4362 Φ2280 | 2520 |

| WH-5.0 | 5.0 | ≤0.6 | 15 | 4576 Φ2402 | 3000 |

| WH-6.0 | 6.0 | ≤0.6 | 15 | 4900 Φ2582 | 3150 |

| WH-8.0 | 8.0 | ≤0.6 | 18.5 | 5405 Φ2805 | 4500 |

| WH-10 | 10 | ≤0.6 | 22 | 5795 Φ3018 | 5500 |

| WH-15 | 15 | ≤0.6 | 30 | 6475 Φ3450 | 6600 |

| WH-20 | 20 | ≤0.6 | 37 | 7535 Φ3805 | 7000 |

| WH-25 | 25 | ≤0.6 | 37 | 7995 Φ4078 | 8500 |

| WH-30 | 30 | ≤0.6 | 52.5 | 8385 Φ4330 | 9200 |

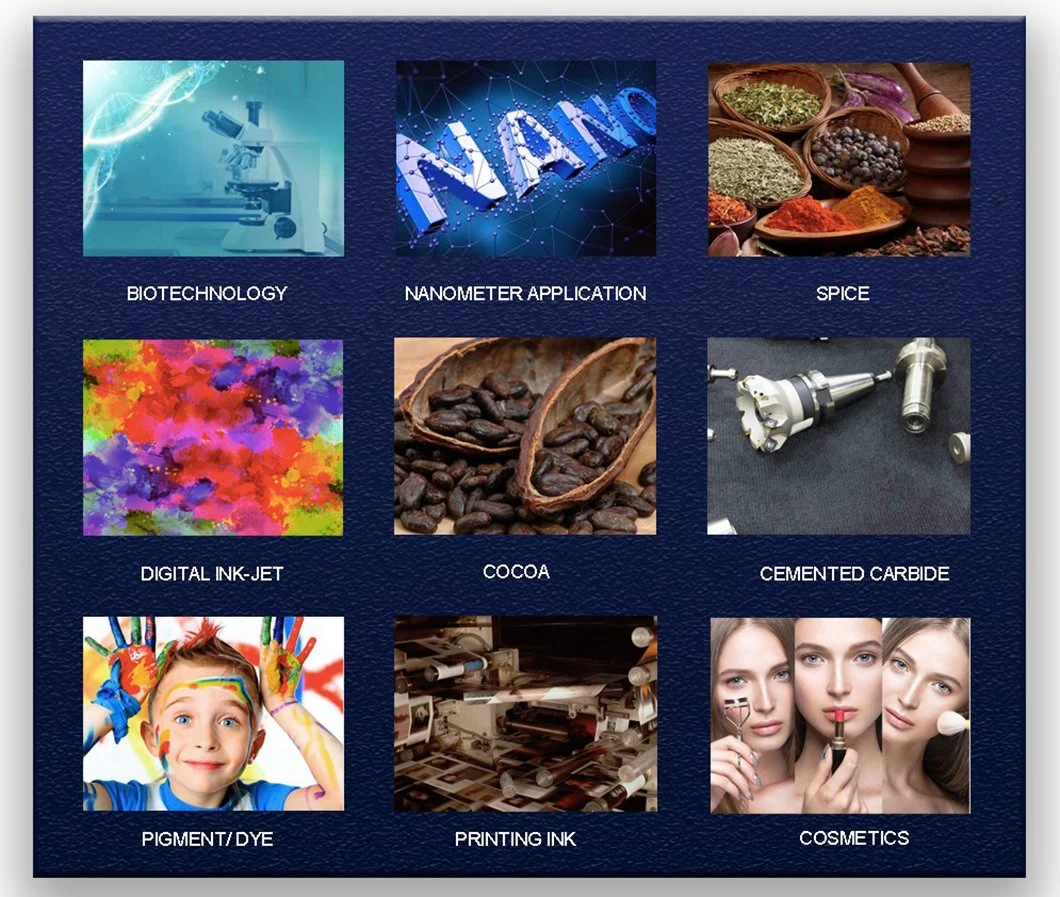

Application Range

WH series double helix cone mixer is suitable for chemical industry, pharmaceutical industry, dyestuff, petroleum industry, metallurgical industry, construction material and etc. Such as in the mixing, reaction, drying, cooling of powder and powder(solid-solid), powder and liquid(solid-liquid), liquid and liquid.

About us

About us

Shandong Karvil Machinery Technology Co., Ltd. is specializing in the research, design, manufacturing and sales of mixing machine, grinding equipment and reaction machine. The company is committed to advanced technology of machine, strict quality control standards and perfect sales service experience to achieve a win-win situation with our customers.

Karvil products have been successful used in the field of powder processing, food, medicine, fine chemical industry, cosmetic, adhesives, paints, inks, dyes, pastes, organic solvents and ceramics, etc.

Karvil engineering team constantly explore new technical points and promote perfect solutions for our clients through efficient communication according to the production application.

Our company has a series of strict standards system to control the purchase of raw materials, the rationality of design, manufacturing process, during inspection, product inspection, which could ensure the high quality of our products and create value for our clients.